5 tech trends mingling with bio-inspired design

<p>Lobster-eye telescopes and 3D-printed stem cells. Where is bio-inspired design popping up next?</p>

Lobster by Richard Griffin via Shutterstock

Bio-inspired design is showing up in technology projects big and small, from telescopes inspired by lobster eyes to see more of space to swellable microneedle arrays that provide safer skin grafts, based on an insect with a similar swellable proboscis.

Here is a look at how bio-inspired design is finding its place within five ascendant technology trends, which I spoke about at a recent talk at Indian Institute of Science in Bangalore.

1. The Internet of Things

The automation enabled by our success at managing information has evolved a world in which machines now talk to and manage each other. One example of this is smart metering, in which the electrical energy draws of individual households are communicated to a central manager, and power production and distribution is meted out in a bottom-up way that avoids shortages and waste.

Regen Energy of Montreal is a company that manufactures an in-home router that does something similar with appliances at a household level. Based on the algorithms of eusocial insects such as bees, the router reads the energy draw of each appliance and schedules its activation in order to avoid peak loads and high costs.

Automobile manufacturers such as Nissan and Volvo also have investigated similar algorithms in their quest for safer vehicles. Nissan long has been active in the research and development of autonomous vehicles for both safety and congestion relief. In 2009, it unveiled its Eporo robot car concept based on the schooling behavior of fish. Collision avoidance is based on relative positioning, but the behavior algorithms are defined by concentric zones. The robots have been programmed to avoid collisions in the near zone, travel side by side, matching distance to speed, in the next zone, and to catch up to any unit in a far zone. The company has used these concepts in refining its Safety Shield technology, a six-stage collision avoidance system.

2. Expanding spatial frontiers

Many well-known examples of bio-inspired design innovation came as a result of seeing something at a new scale: the lotus effect, Velcro and the sharkskin swimsuit.

I have written here about the 4D microscope at Caltech, which is emblematic of the progress made in seeing the very small. This research progress has not been wasted, as many of those in the applied sciences have taken advantage of being able to see and manipulate material at the nano and micro levels. An example is the use of nanowires to boost solar energy collection in photovoltaic cells, as tested by MIT and the Niels Bohr Institute.

Wyss Institute experimenters have been able to bind DNA strands with fluorescent dye to other DNA on target molecules, causing them to blink and be more easily seen. This technique has overcome the problem with the so-called "diffraction limit," where light bends around objects and blurs them to the human eye (0.2 micrometers). The dye method will offer a cheaper alternate to current microscopy.

It is not just the small that we can now see better, but also the large -- space, for example. The lobster was the inspiration for the lobster-eye telescope. The lobster is a long-life creature that hunts at night in the murky depths and relies on eyesight completely unlike our camera eye. It uses what are essentially mirrors in a tube to collect as much light as possible and focus it on its retina. The lobster-eye X-ray telescope has a wide field of vision, 1,000 degrees square or more.

3. Biological paradigms

Biological paradigms themselves are a major technological trend, especially in the fields of robotics and biomaterials.

Companies such as Boston Dynamics and Festo have been successfully mimicking animal locomotion for years, producing the fastest land robot on earth and an incredible vehicle that flies like a bird, respectively. The Stickybot at Mark Cutkosky's lab at Stanford built on the research work on the gecko by the CIBER lab at UC-Berkeley. George Whitesides' lab at Harvard is pursuing softbots and how flexibility can increase performance. The Robobee is an insect-like micro-air vehicle from the Harvard Microrobotics Lab that is smaller than a quarter. The Meshworm at MIT and the Robojelly at Virginia Tech are two others in an exhaustive list.

Three examples from the field of biomaterials give some sense of the range of applications extant in this discipline.

Researchers from the Biomedical Research Centre of Granada, Spain, recently have reported a successful technique to make artificial bone ex vivo from stem cells and an activated carbon support. This is the first time that such a complex tissue has been made outside the body using cell differentiation.

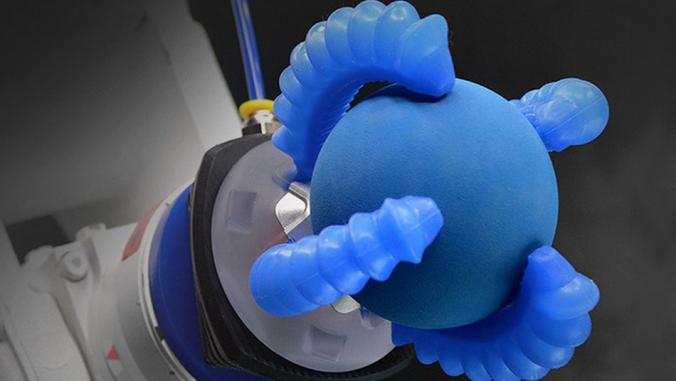

The proboscis of an insect inspired the design of a swellable microneedle array by an interdisciplinary team of researchers at Harvard. The endoparasite Pomphorhynchus laevis swells its proboscis to attach to its host's intestinal wall, and the team developed a biphasic microneedle array that mechanically interlocks with tissue through swellable microneedle tips, achieving about a 3.5-fold increase in adhesion strength compared with staples in skin graft fixation. The swellable tips of these micro-cones surround a polystyrene core and have high adhesion strength when swollen. This design provides universal soft tissue adhesion with minimal damage, less traumatic removal, reduced risk of infection and delivery of bioactive therapeutics.

The storage and delivery of biomaterials is the focus of the final example from Biomatrica of San Diego. Based on the ability of tardigrades to lose 98 percent of their body moisture and still live, the system provides a method for storing and shipping lab samples without the use of refrigeration. The tardigrade is a multi-extremophile, a small common invertebrate that can survive for a decade in the dry state, withstand 1,000 times the radiation that we can and live through the vacuum of space. It does it, in part, by replacing the lost water with trehalose, a sugar that provides support to precious membranes while in this anhydrobiotic state. After drying, samples are stored at room temperature and revived with water when needed.

4. The human/machine interface

Google, Nokia and Apple all have patents on mobile augmented reality devices that close the gap between the mind and extensions of our senses. Google Glass, for instance, changes the way incoming data is streamed into our consciousness: continually, rather than by discrete selection.

The field of biomechanics has been at this game for a long time, yielding advances in the development of exoskeletons, such as the HAL 5 (Hybrid Assisted Limb) by Cyberdyne of Japan. This full-scale cyborg suit, for instance, picks up brain signals in the skin in order to activate its artificial muscles.

These are examples of how a mechanical device can be integrated into the workings of a human body, but I believe that the blurring of the lines between organic and artificial will continue in another, more revolutionary manner. Our machines will become more organic, and what will drive this, in my opinion, will be biomedical research.

At Oxford University, researchers have micro-dot-printed live stem cells and nutrients from a precise 3D printer, and been able to form bilipid layers and also express specific proteins. Membranes and conductivity are now possible, although a living tissue is many years away. What this means is that this kind of manufacturing can produce material, albeit organic, that can do work -- in other words, a machine. While much of the focus is on in situ surgery and repair of tissue, the potential is there for an extension of capabilities at the human/machine interface.

Similarly, at MIT's Institute of Medical Engineering and Science, bioengineers have been able to produce heart muscle tissue using the layering of 3D printing and other techniques from the microelectronics industry. What is important about this work is that it begins to implement what scientists know to be key in replicating natural systems: building in a hierarchy of scales that all work together to perform a function or functions.

5. Mass customization

The revolutions in information, communication and manufacturing have changed the relationship between designer and manufacturer -- and, indeed, consumer and product. The scanning of an object, rendering in CAD, and subsequent production by additive manufacturing is now commonplace, if limited in scope. This sequence allows for exact measuring for need, just-in-time manufacture and manipulation of a file to produce a custom version. Scott Summit's Bespoke Innovation, now a part of 3D Systems, makes custom prosthetic devices based on this.

The Urbee prototype car by Kor Ecologic of Winnipeg, Canada, was the first car body to be made with additive techniques, and is an instructive example. The designers wanted an extremely aerodynamic shape with a low drag coefficient of 0.15, but making the body parts in a traditional fiberglass mold layup was expensive in time and labor. Instead they 3D-printed it out of ABS plastic in 10 parts in half the time and for a lot less money. This is a case of how this relatively new technique can be used to solve problems that others cannot.

The technique continues to evolve, with people such as Behrokh Khoshnevis, a professor of industrial and systems engineering at the USC's Viterbi School of Engineering of University of Southern California, pushing the boundaries of scale, by building houses from big gantries and concrete nozzles, and the Joris Laarman Lab in the Netherlands where they have developed the AOM or Anti-gravity Object Modeling technique. Here a thermo-set plastic is squeezed out of a nozzle and set in mid-air by two heat guns.

These trends appear self-evident to me. The contribution that bio-inspired design makes to them is just beginning.

Lobster image by Richard Griffin via Shutterstock.com