It's probably fair to say that nobody expressly set out to devise a sunscreen to bleach coral reefs or a yoga mat to emit carcinogens. Yet toxic substances circulate in waterways and bloodstreams, leached out from all the consumables of everyday life.

Shortsightedness and paltry data in the cycles of product design and engineering are partly to blame for this collateral damage of modern chemistry. Most product designers are unlettered in chemistry, and the practice of green chemistry remains in its early years. Even a basic count of all the industrial chemicals in use is scarce — somewhere over 80,000, according to the U.S. Toxic Substances Control Act Inventory, although the EPA total for recent output is less than 9,000.

It's simply asking too much of most people formulating a consumer product only to include ingredients that are proven not to harm living systems.

But what if design teams seeking safer ingredients didn't have to know much about the molecules that comprise the stuff they're making? What if they had a handy menu that graded each chemical? In theory, picking a less-toxic choice could be as simple as shunning an "F" or "C" ingredient for an "A" or a "B" on the list.

We really saw this as a key to unlock in order to improve safe and circular chemistry.

That's the vision being advanced by ChemFORWARD, a mission-driven nonprofit backed by leading corporations with serious ambitions to accelerate safer chemistry. The effort is attracting pioneers in green chemistry, design and data to build a first-of-its-kind clearinghouse to help design teams and supply chains ditch hazardous chemicals for good.

Leaders on board

"We really saw this as a key to unlock in order to improve safe and circular chemistry," said Mike Werner, circular economy lead at Google, who serves on the nonprofit's advisory board. The search giant pushes for safer chemistry and a circular economy on myriad levels, including within its office spaces, at its data centers and inside the devices it sells. "ChemFORWARD fits [into] this really big important puzzle toward making materials healthy and safe."

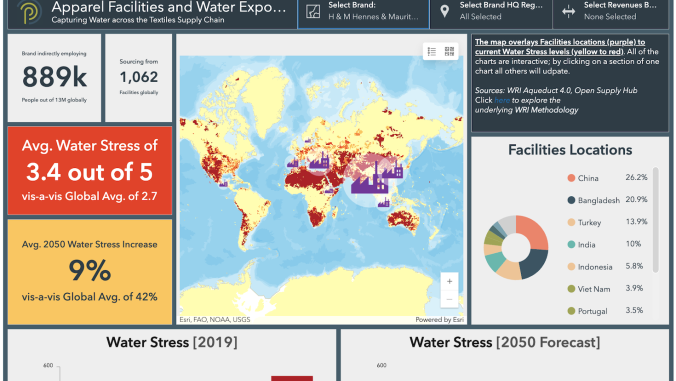

Google is among ChemFORWARD's roster of "co-design" partners that includes Sephora, Target, Levi's, HP, Levi Strauss, H&M, Nike, Steelcase and Method, each recognized for various leadership efforts toward safer chemistry. Last year, for example, Sephora became the first major cosmetics retailer to broadcast its policy on chemicals. Target's Sustainable Product Standard came on the scene in 2013. Nike has its own Chemistry Playbook. Levi's innovations include its recyclable Wellthread denim line. Other ChemFORWARD partners include the Environmental Defense Fund (EDF) and Zero Discharge of Hazardous Chemicals.

ChemFORWARD's technical advisory board is led by Art Fong, Apple's green chemistry lead. Corporate scientists and chemists also come together via ChemFORWARD for regular meetings and peer reviews with third-party toxicology firms. The nonprofit is betting that teaming up with such pathfinders will help spark lasting industry innovation via its tool, in the process lowering the cost for even small companies to find safer chemical alternatives for their products.

"Our intention is to reverse decades of negative impacts from the inundation of toxic chemicals that we find in our products, our economy, our environment and our bodies," said ChemFORWARD Executive Director Stacy Glass, who has led the effort from a project within the Cradle to Cradle Products Innovation Institute to its current iteration, housed within the Washington, D.C.-based Healthy Building Network, a nonprofit that advocates for sustainable building materials. "We need new solutions, new ways of thinking about things to have safe, circular products."

We are fundamentally changing the way that chemical hazard data is created, maintained, distributed and financed.

ChemFORWARD seeks not only to display what chemicals not to use, but also what's available instead. This aim progresses away from the longtime industry reliance on restricted substances lists that can leave product makers empty-handed, while liberating data that until recently has been trapped in various PDF reports or proprietary databases.

ChemFORWARD seeks to stand apart from other data plays by building bridges in the supply chain with its "collaborative, harmonized" approach. "We are fundamentally changing the way that chemical hazard data is created, maintained, distributed and financed," Glass said.

What's inside

However, ChemFORWARD is entering an area that's already seeing a lot of activity. Multiple hazards assessment standards are available in increasingly usable formats to help companies identify problematic chemicals. The for-profit firm Scivera, launched in 2008 in Charlottesville, Virginia, offers a subscription database SciveraLENS, with color-coded grades for chemicals based on their inherent hazards.

ChemFORWARD's web-based software pools together data from some of the best-known chemicals assessment methodologies. A color-coded letter grade rolls up information from the United Nations’ Globally Harmonized System of Classification, Cradle to Cradle (on material health) and the EPA SaferChoice Safer Chemical Ingredients List. That results in offering users more than 50 pieces of interpretation and over 20 human and environmental endpoints, such as around neurotoxicity or aquatic toxicity, for each chemical.

A view inside a ChemFORWARD display of dimethyl phthalate, used in plastics.

"The work that ChemFORWARD is doing and proposes to do will provide important additional information to a community of organizations seeking real-world data to better understand the safety implications of their materials choices," said green chemistry trailblazer John C. Warner, a distinguished research fellow at synthetic biology startup Zymergen.

Think of nearly any consumer-product chemical villain that's dominated recent headlines for disrupting ecosystems or being linked to cancer or hormonal havoc. Chances are ChemFORWARD is building a collection of alternatives to it. These include ortho-phthalate plasticizers found in flexible toys, UV-blocking oxybenzone in sunscreens and halogenated flame retardants in electronics. ChemFORWARD has portfolios of alternative cleaning solvents, cosmetics preservatives and fragrance fixatives. The goal is for ChemFORWARD to scale up from about 200 to 2,000 safer chemicals in 2021.

"The more technical person can see the technical data they need," Glass said. "But most companies need, ‘Can I use it [or] can I not use it?’ for an answer."

More than skin deep

ChemFORWARD is building clearinghouses for electronics and food packaging, but one of its earliest repositories coalesces data in beauty and personal care, with hundreds of safer alternatives. Someone shopping around to include a safer surfactant in a skin cleanser or an emollient in a moisturizing lotion can consult the tool for the green "A" or "B" options.

Sephora, which is mindful of its many eco-conscious young customers and became a co-design partner with ChemFORWARD in March, recently took steps to advance beyond its restricted substances list. The company says 94 percent of all the products it sells eliminate potentially negative "high-priority" chemicals. The Clean at Sephora label for sustainable beauty care products in its catalog features goods from more than five dozen smaller companies, including BeautyCounter.

"We knew the importance of creating a baseline expectation for all brands in terms of safety and the environment," Carley Klekas, Sephora's senior manager of product sustainability, said. "Sephora already had rigorous requirements in place, specifically with our in-house brand, Sephora Collection, that goes beyond EU regulations, but we also wanted to expand this even more across the brands we carry."

These chemicals used in cosmetics display letter grades according to safety.

It teamed up with ChemFORWARD and EDF on a research project that prioritized four chemical categories common within beauty and personal care: preservatives; benzophenones; silicones; and ethanolamines. Sephora then sponsored chemical hazard assessments for the alternative ingredients named in the research. As a result of the partnership, safer alternatives have been assessed for 73 percent of Sephora’s high-priority chemicals — and made available to industry via ChemFORWARD.

"We needed a credible and innovative resource to help us assess alternatives to chemicals within our policy, to ensure they were safe, and that we were avoiding regrettable substitution," Klekas said. "We know this is important work to be done and will ultimately help showcase that there are safer alternatives to the high-priority chemicals we seek to reduce in our assortment, while also help the industry identify gaps where more innovation is needed."

The innovation puzzle

Glass sees ChemFORWARD’s highest mission as its potential for furthering innovation. But that requires buy-in not only from retailers and product manufacturers, but also from the chemical producers themselves. The process of making chemical substitutions is only one step along the path to optimizing shiny, new, safer chemicals, which Glass hopes to help propel.

Enter Pat Harmon, industry manager at chemicals powerhouse BASF. He’s been involved with ChemFORWARD for many years after meeting Lauren Heine through a Green Chemistry & Commerce Council (G3C) event. Heine was then executive director of the nonprofit Northwest Green Chemistry and had just joined MaterialWise, the early iteration of ChemFORWARD, where she's now director of safer materials and data integrity.

BASF’s sustainability strategy hinges upon developing chemicals that advance sustainability, called "accelerators," which account for more than 25 percent of its sales. Ninety-five percent of BASF's products have been evaluated for potential sustainability contributions. BASF has a history of involvement in collaborative assessments, and it quantifies the sustainability benefits of its products through life-cycle assessments and its Sustainable Solutions Steering methodology.

It's really powerful in terms of thinking about moving to green chemistry.

Harmon aligned with Heine on the need for better third-party assessments for alternatives to troublesome ortho-phthalates, which are tied to multiple health problems. He also liked what she described of how the fledgling nonprofit chemical clearinghouse might lower the cost to companies of chemical assessments while moving away from "negative lists." ChemFORWARD's involvement with leadership brands and retailers, which are ultimately BASF’s downstream customers, also helped to elevate the case for BASF getting involved.

Eventually, BASF shared details for ChemFORWARD about several of its plasticizer accelerators, including its ortho-phthalate alternatives Hexamoll DINCH and Palatinol DOTP. These are used in flexible PVC and in a broad range of applications including children’s toys, yoga mats, wiring cable, vinyl flooring and automotive interiors.

A bridge?

"Now, chemical suppliers have the option to market their safer alternatives and to validate their low-hazard claims through an independent, trusted platform," Glass said. "In this way, we create a bridge between chemical suppliers, their customers and prospective customers with data that has been traditionally hard to come by, difficult to interpret and sometimes hard to trust."

Harmon sees ChemFORWARD as a useful tool for companies that ultimately use BASF’s chemicals as well as a resource that can help move safer chemistry forward in industry, demonstrating for BASF's customers the value of the safer decisions behind their product formulations. And the involvement with CHEMForward may help BASF to identify potential market gaps in areas where the number of attractive chemical alternatives is slim.

"This is why the ChemFORWARD project is so important," Harmon said. "It’s one of the ways to help understand that you're making the right decisions to move to new substances. I would really like to see this approach be used more and more." For example, what if ChemFORWARD could grow to include the broader area of plastics additives in addition to plasticizers, such as flame retardants and light stabilizers? That could bring more of the plastic industry onboard, he added.

"If you make it broader for the whole plastics industry, then you have a lot of people who would have interest in using this type of tool," Harmon said, optimistic that ChemFORWARD may help to advance plastics circularity longer term. For example, if it identifies safer plastics used, say, in medical equipment that's currently discarded, then more IV bags or other consumables finally might be recycled without the possibility of circulating harmful chemicals into the marketplace and the environment, Harmon said.

Here's a view of inherent hazards for benzophenone, known to damage coral reefs. It has been banned in sunscreens in Hawaii.

ChemFORWARD's small team hopes to encourage more chemical suppliers to get involved by providing them a means to bring forth their safer chemicals in a way that’s trustworthy, verified and peer-reviewed by a third party, also broadening the availability of their chemicals for certifications and reporting. Companies can use this information for marketing purposes, including for consumer labels, but it's also critical for risk management and verifying internal claims about a product.

"As we get more and more eyes on our platform, we'll be able to make that case even more strongly that: 'Hey, chemical suppliers, if you have good stuff and you want to verify those claims, this is a great place to do it,'" Glass said. "We feel a tremendous sense of urgency to not only stop unknowing toxic chemical exposure, but to empower those who are working to create a safe and circular future for all."

Data driven

Glass spent a decade in green building, serving as VP for the built environment at the Cradle to Cradle Products Innovation Institute, which shaped in 2016 the earliest version of ChemFORWARD. Research across industries, up and down supply chains, found that companies lacked information to use better chemistry. Good attempts by other nonprofits had failed to gain traction. Recognizing a larger industry need, the institute spun out the effort, which currently counts less than 10 staff members distributed across the U.S. and a network of toxicologists.

I realized this was a data organization problem, our not knowing what was in our stuff and what we’re exposed to.

"I realized this was a data organization problem, our not knowing what was in our stuff and what we’re exposed to, and the incredible tax this exposure is causing to society," Glass said. "I’m not a chemist, I’m not a toxicologist — I said, we can fix this. I see the solution clearly. I’ll take any data solution, any scalable solution, that will get this information into the hands of designers and formulators so (they) can make safer decisions."

It's possible ChemFORWARD ultimately could feed data into life-cycle analysis or supply chain management tools. It can't hurt to have Google as a partner, and it's worth noting that the advisory board's latest addition is Kimberly Shenk, co-founder of the AI-driven supply chain transparency startup Novi.

The movement, however, has a long road ahead. It's still relatively cheap for companies to crank out new molecules, and the chemicals industry is a powerful economic engine and lobbying force.

Nevertheless, ChemFORWARD and others pivoting away from the conventional focus in managing chemical risks and instead toward making decisions based on inherent toxicity is a huge paradigm shift, said Mark Rossi, executive director of Clean Production Action, who also created the GreenScreen for Safer Chemicals hazard assessment method with Heine.

"It's really powerful in terms of thinking about moving to green chemistry," he said. "All chemistry should be green chemistry, and how do you get there? This is all part of that movement toward making choices based on hazards."